Remanufacturing

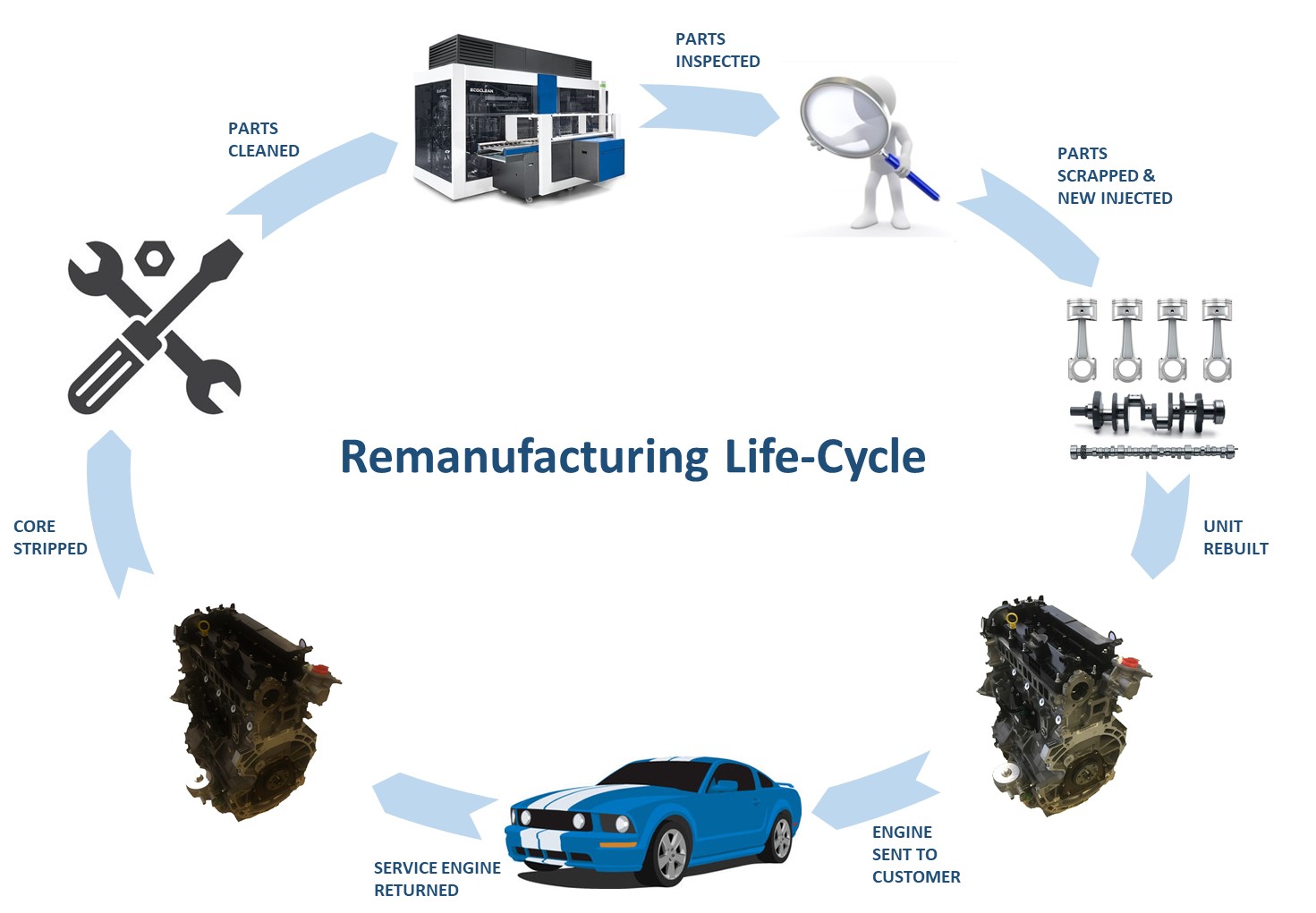

Remanufacturing is a process of bringing used products to a "like-new" functional state with warranty to match. The practice is regarded as a more sustainable way of manufacturing as it causes less harm to the environment than conventional manufacturing and is more profitable. Products generated through a high standard Remanufacturing process have comparable quality to equivalent new products but require 50% to 80% less energy to produce. Remanufacturing can also provide 20% to 80% cost savings in comparison to conventional manufacturing.

Generating process efficiencies and cost savings from warranty and aftermarket replacement parts, for over 40 years MCT ReMan Ltd has been the selected Remanufacturing partner of leading automotive OEMs such as GM, Ford & JaguarLandRover for a range of powertrain product applications.